Felite™ EDM resin results in stable operation of deionized water with electrical conductivity consistently below 18 μS/cm, increasing processing capacity by up to 30%.

Home » EDM Resin Manufacturer

Home » EDM Resin Manufacturer

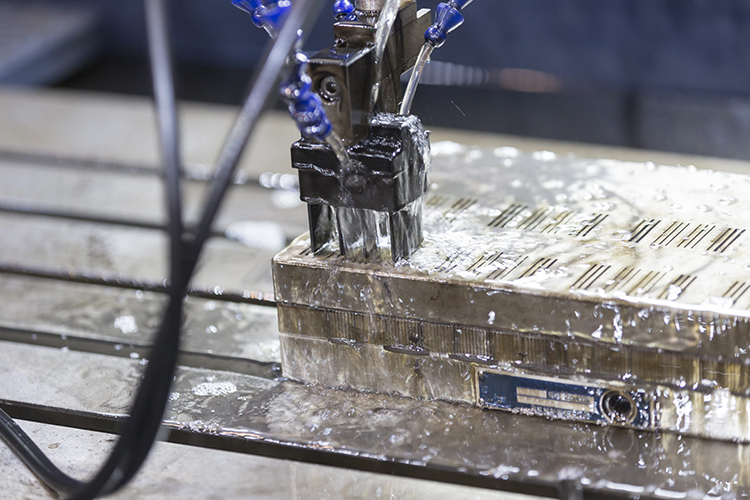

Precision and accuracy are essential in Electrical Discharge Machining (EDM), a highly technical process. Deionized water that meets the process’s specific criteria will help you get better results, lessen electrode wear, and extend the life of your EDM machine.

Due to its excellent electrical insulating properties, deionized water is the most commonly used fluid dielectric liquid in wire EDM. It effectively cools the workpiece, removes eroded material, and keeps the cutting surface from becoming thermally stressed. Quality EDM resin, like Felite™ EDM resin, is essential for producing high-quality deionized water for EDM because it filters contaminants out of the dielectric fluid used in machining, which has a major impact on the precision and efficiency of the EDM process.

Deionized water with low electrical conductivity, typically below 20 μS/cm, is in high demand because the quality of the working fluid in slow wire EDM greatly affects cutting speed, surface roughness, and machining precision. Felite™ Resin Technology has created unique mixed bed resins, Felite™ FMB401-B & Felite™ FMB402, to cater to the slow wire EDM industry’s particular water quality needs. It’s a simple and convenient option for slow wire EDM because it’s a pre-mixed bed resin that can be used straight in an ion exchanger. Customers have responded positively to Felite™ mixed bed resin, which has led to stable operation of deionized water with electrical conductivity consistently below 18 μS/cm and an increase in processing capacity of up to 30%.

Would like to request a sample for quality evaluation? Or, request a quote?

EDM resin is an ion exchange resin used in the deionization process to create ultra-pure water. Producing high-quality, deionized water is simple and inexpensive with this technology due to its great capacity to remove TDS(total dissolved solids).

To remove both positively and negatively charged ions from water, EDM resin is one-of-a-kind because it comprises pre-mixed strong acid cation resin in H+ form and strong base anion resin in OH- form within a single unit.

As water is passed through EDM resin, the positively charged ions are changed to hydrogen ions and the negatively charged ions are converted to hydroxide ions, producing high-quality, deionized water devoid of other contaminants and total dissolved solids and resulting in a resistivity level of up to 10M that is ideal for the EDM industry. To get the purest water and extend the lifespan of EDM resin, it could be used in addition to other demineralization methods like reverse osmosis.

The EDM industry makes extensive use of EDM resin because of its adaptability. The outcomes of your EDM machining jobs will be more stable and consistent if you use high-quality EDM resin. These are some typical examples:

EDM resin is used to cleanse and cool the electrodes during the cutting process in wire EDM equipment. This serves to prevent the collection of dirt and contaminants, which can impair the accuracy and efficiency of the machining process.

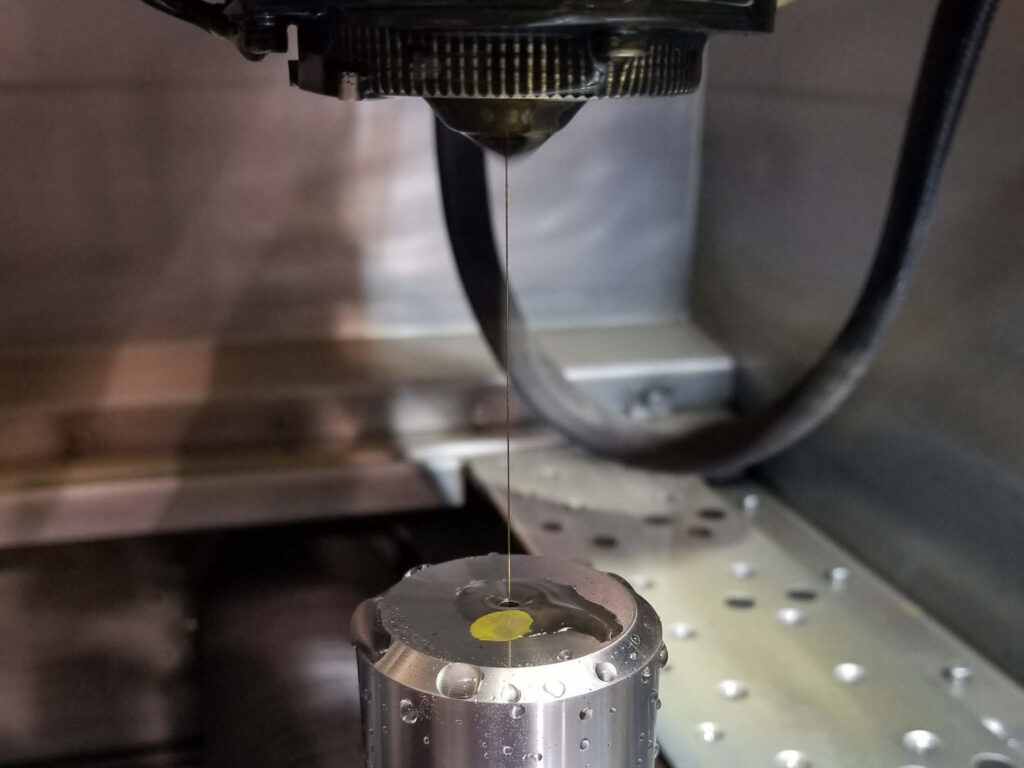

EDM resin is used in sinker EDM machines to cleanse the electrodes and prevent debris from accumulating on the electrode surface. This keeps the electrodes sharp and free of impurities, resulting in precise and efficient machining.

As a means of cleaning the dielectric fluid in hole drilling EDM machines of dirt and impurities, EDM resin is utilized. As a result, the quality and accuracy of the machined holes is improved.

Microscopic electrical discharge machining (micro-EDM) uses EDM resin to achieve machining accuracy. For micro-EDM to be effective, the resin used must be free of pollutants that could dull the electrodes.

EDM resin aids in the purification of the water used in the EDM process, which can result in enhanced machining precision. This is because contaminants in the water might create inadvertent sparking, resulting in errors in the machined component. By decreasing the conductivity of the water, EDM resin can reduce the likelihood of sparking, resulting in more precise and precise cutting.

EDM resin aids in the purification of the water used in the EDM process, which can result in enhanced machining precision. This is because contaminants in the water might create inadvertent sparking, resulting in errors in the machined component. By decreasing the conductivity of the water, EDM resin can reduce the likelihood of sparking, resulting in more precise and precise cutting.

There is a correlation between the usage of EDM resin and a decrease in electrode wear. When the electrodes erode due to impurities in the water, the lifespan of the system decreases and maintenance expenses rise. As EDM resin is effective in absorbing and removing these contaminants, it can help to lengthen the lifespan of the electrodes, which will save money in the long run.

EDM resin not only helps the electrodes last longer, but it also protects the EDM machine itself from wear and tear. Impurities in the water can wear out parts of the equipment over time, resulting in malfunction or even total breakdown. In order to prevent this buildup and extend the life of the machine, EDM resin can be used to purify the water.

The surface quality of the machined object can be enhanced with the aid of EDM resin. Surface imperfections brought on by water impurities can result in an unsatisfactory final product. EDM resin can aid in the creation of a more uniform surface finish by decreasing the conductivity of the water.

More efficiency in the EDM process is possible with the help of EDM resin for water purification. Faster machining times, more productivity, and lower costs are all possible outcomes of minimizing sparking and electrode wear.

Tom H., Engineering Manager

Mark S., Quality Control Manager