Applications include pH adjustment; Water softening; Decolorization; Deionization; Nitrate removal, etc.

Home » Ion Exchange Resins in Aquarium Industry

Home » Ion Exchange Resins in Aquarium Industry

Aquarium enthusiasts know that maintaining a healthy and thriving aquatic environment can be challenging. Water quality is crucial for the well-being of fish, plants, and other aquatic life. One way to ensure good water quality is by using ion exchange resins.

Ion exchange resins are used to remove impurities from water and regulate pH levels. They are commonly used in the aquarium industry to improve water quality and support aquatic life. Whether you are a seasoned expert in the perplexing world of aquariums or a complete beginner, understanding the role and impact of ion exchange resins is vital.

Felite™ ion exchange resins for Aquarium and Reef industry have been strictly treated to achieve the highest level of purity.

Ion exchange resins are commonly used in the aquarium business to filter out contaminants including chlorine, chloramines, and heavy metals from municipal water supplies. These contaminants have the potential to harm marine life and reduce the overall quality of water. Ion exchange resins aid in maintaining a balanced and sanitary aquatic ecosystem by absorbing and exchanging ions.

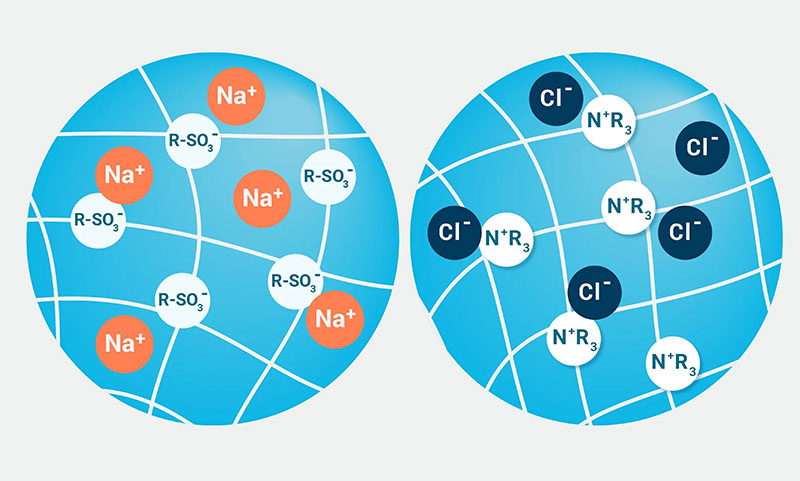

Each type of ion exchange resin has its own specific ion form, such as Na and H for cation resins and Cl and OH for anion resins. They can function independently, or in custom-made tandem configurations. It’s crucial to choose the correct ion exchange resin for your aquarium’s demands.

Several advantages for aquatic life and aquarium keepers can be gained by using ion exchange resins, including those listed below.

In order to safeguard the environment, reverse osmosis technology may filter out hazardous compounds in water; nevertheless, this process is very expensive. If you want to make reverse-osmosis water, you’ll have to flush around 200 gallons down the drain to get 50 gallons’ worth. We can immediately put ion exchange’s zero-waste benefits to work for us.

The health and survival of aquarium inhabitants depend on constant attention to the aquarium’s pH balance. By eliminating surplus ions that could otherwise cause pH changes, ion exchange resins can aid in maintaining a consistent pH level.

By eliminating contaminants that contribute to water turbidity or colouring, ion exchange resins can increase water clarity. If done properly, this can make aquariums more pleasant to the eye.

Chlorine and other chemicals found in municipal water supplies can be toxic to fish and other water organisms. Because of the efficiency with which ion exchange resins can remove these contaminants, the water quality in which fish, plants, and other aquatic life can thrive is greatly improved. However, in order to extend the useful life of the ion exchange resin, its use is ideally combined with activated carbon.

When there are too many nutrients in the water, algae blooms are a regular problem in aquariums. By removing organic debris and these surplus nutrients, ion exchange resins help lower the potential for algae growth.

As a whole, there are numerous advantages to employing ion exchange resins in aquariums for both the fish and the people who like watching them.

Using ion exchange resins in an aquarium requires careful consideration of several criteria, including the type of ion exchange resin, the size of the aquarium, and the special needs of the aquatic life. Here is a detailed instruction for using ion exchange resins in an aquarium:

Several types of ion exchange resins are developed to remove particular contaminants from water. For instance, there are anion exchange resins for the removal of nitrate and organic debris, cation exchange resins for the softening of water, and mixed DI resins for the reduction of TDS. It is vital to select the proper type of ion exchange resin based on the aquarium’s individual requirements.

The quantity of ion exchange resin required depends on the size of the aquarium, the degree of contaminants in the water, and the type of water treatment system employed. In the last step of a 3- or 4-stage RO/DI system, a 10-inch DI cartridge is often installed. More resins may be required for increased exchange capacities in water treatment systems without RO. We recommend using an activated carbon cartridge prior to the DI cartridge to increase its longevity.

Before utilizing the resins, they must be carefully rinsed with clean water to eliminate debris and dust. Several rinses may be necessary if you purchased a 25L or 1 cubic foot box of DI or other resins, as bacteria will inevitably grow during storage and residual contaminants can taint the resin. Even though vacuum-sealed resin packets are less likely to be contaminated, the resins must still be rinsed prior to use.

Typically, ion exchange resins are placed in a filter or cartridge where they can interact with water. Follow the manufacturer’s installation instructions for resin in the filter.

To guarantee the desired impact is reached after employing ion exchange resins in the aquarium, it is essential to test the water quality on a regular basis. Frequently test the water’s pH, ammonia, nitrate, and other significant characteristics.

Eventually, ion exchange resins will eventually become depleted and require replacement. Felite Resin Technologies creates indicator resins that change color to remind customers to replace them when their performance has diminished. The frequency of resin replacement will depend on the type of resin and the water’s impurity level.

By following these steps, aquarium enthusiasts can successfully use ion exchange resins to improve aquarium water quality and sustain aquatic life.

Pablo Hensley - Supply Chain Coordinator

Alex Allman - Purchasing Manager